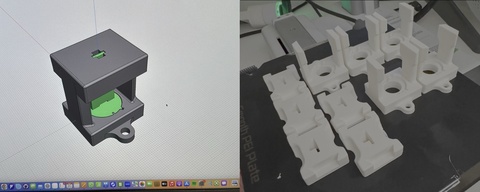

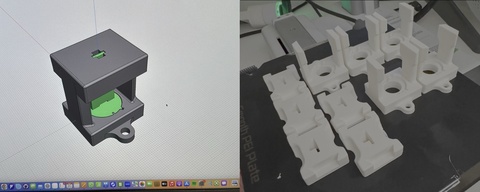

3D Printed Precision Jigs

Development of customized 3D printed supports to improve efficiency and quality in electronic component assembly.

Development of customized 3D printed supports to improve efficiency and quality in electronic component assembly.

An electronic component assembly company needed to improve precision and efficiency in manual soldering operations, ensuring consistent quality and adherence to geometries.

We developed a series of 3D printed supports (jigs) that offer:

40%

Productivity increase

90%

Waste reduction

<24h

Production time for new supports

The introduction of 3D printed supports has transformed our assembly process. Precision has increased significantly and our operators can work more efficiently. The ability to produce new supports quickly allows us to be much more flexible.

Nadia Ponte

Ciari Elettronica SRL

Discover how we can help you achieve similar results with a customized solution for your company